Current location:Home > tilt cylinder seal kit >

tilt cylinder seal kit

2025-08-14 08:41

2025-08-14 08:41

2025-08-14 08:14

2025-08-14 08:13

2025-08-14 08:11

2025-08-14 08:02

2025-08-14 07:03

2025-08-14 06:54

2025-08-14 06:52

2025-08-14 06:39

Latest articles

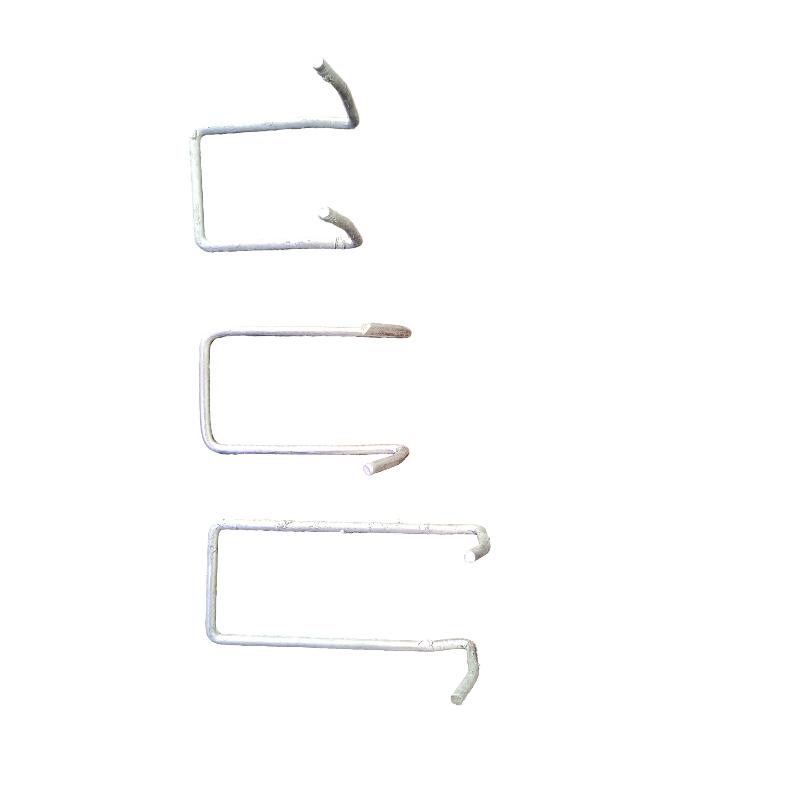

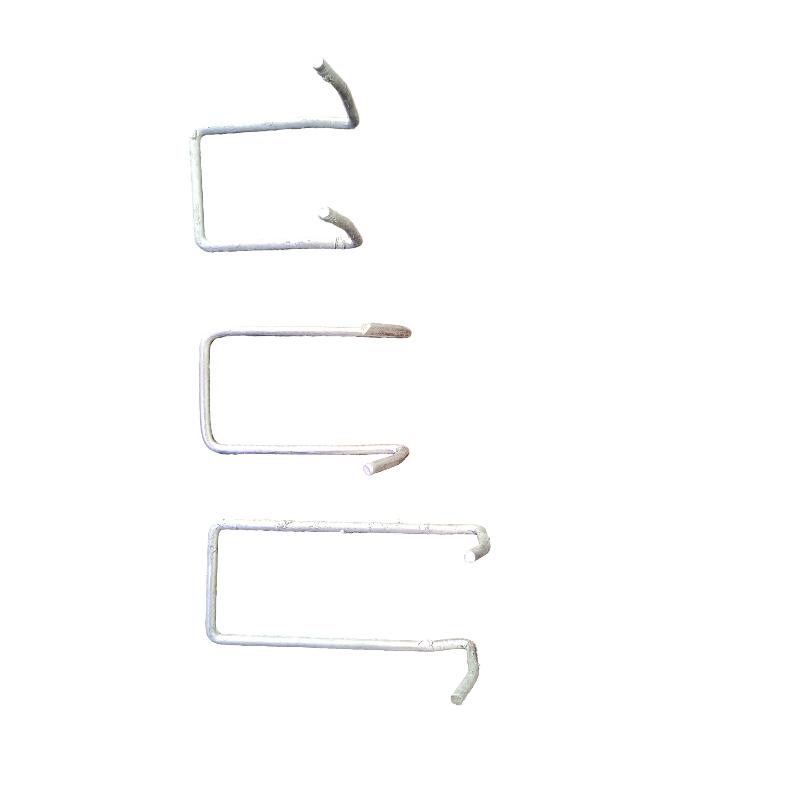

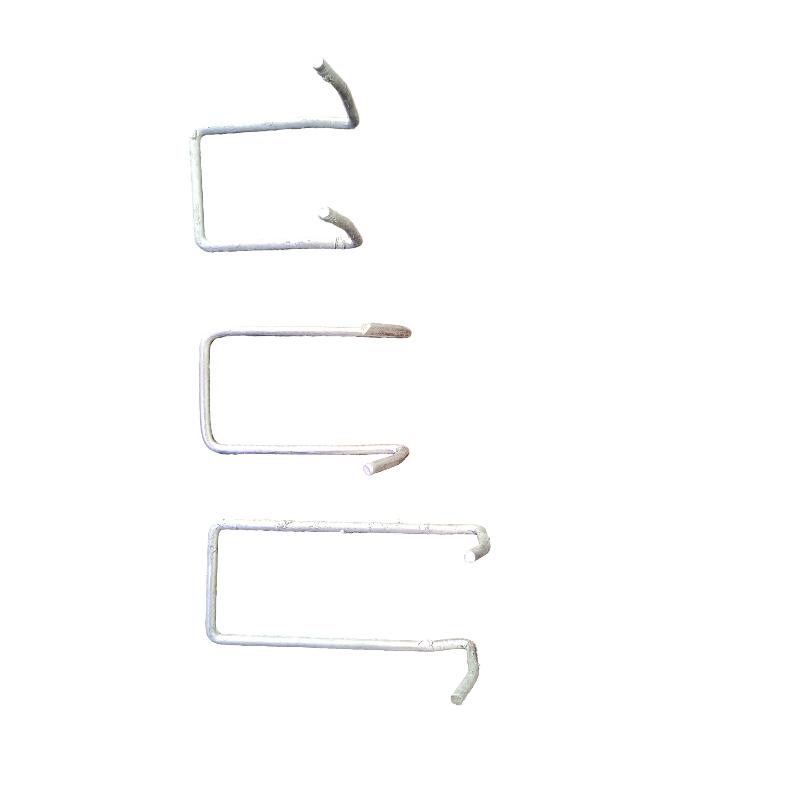

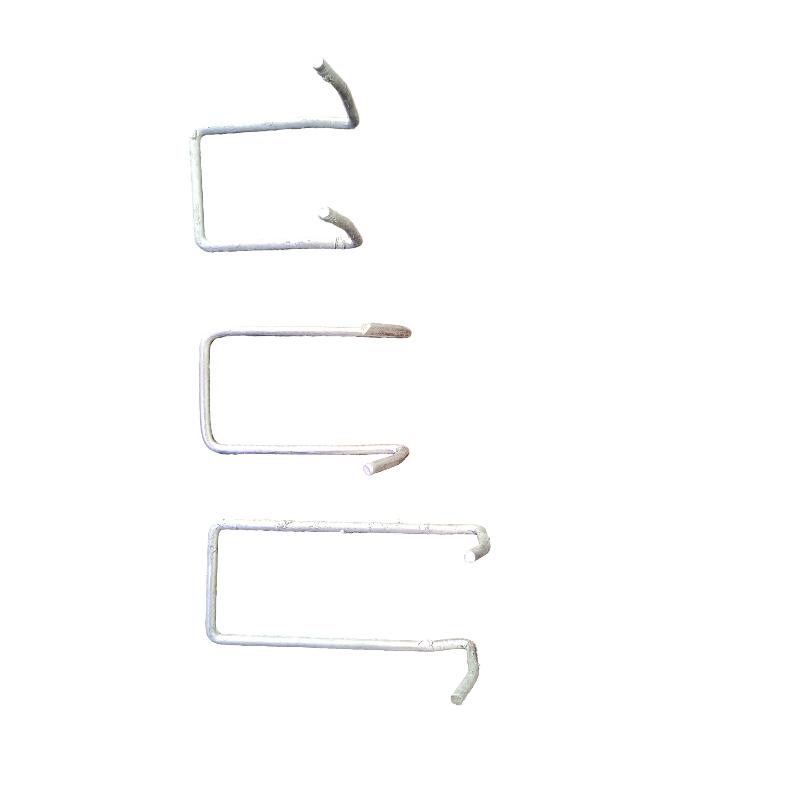

The installation process of cavity wall brick ties is meticulous. They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load

They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.

cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.

They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load

They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.

cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.The process of joint reinforcement involves careful planning and execution. Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction

Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach.

joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach.

Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction

Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction Steel bars, usually made from high-strength, corrosion-resistant materials, are placed within the bed joints during the masonry construction joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach.

joint reinforcement masonry. These bars, known as masonry ties, are designed to bond with the mortar and the masonry units, creating a cohesive structure. Alternatively, fibers can also be used, particularly in modern, more innovative construction methods, offering similar benefits with a different approach.Another critical factor in wire mesh quality is the choice of materials. Stainless steel is a popular choice due to its resistance to corrosion and longevity. However, depending on the specific application, other materials such as Galvanized steel or Black wire may be more appropriate. The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced reinforcement wire mesh size.

reinforcement wire mesh size.

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced reinforcement wire mesh size.

reinforcement wire mesh size.